Types of Turbines

Over the past years, various turbines have been invented and put into operation, which are made for different applications, but generally they are divided into four general categories

Gas Turbines

Steam Turbines

Water or hydraulic turbines

Wind Turbines

Ahar Company operates in the field of control and protection of three types of these four types of turbines (gas, steam and water turbines)

Gas Turbine

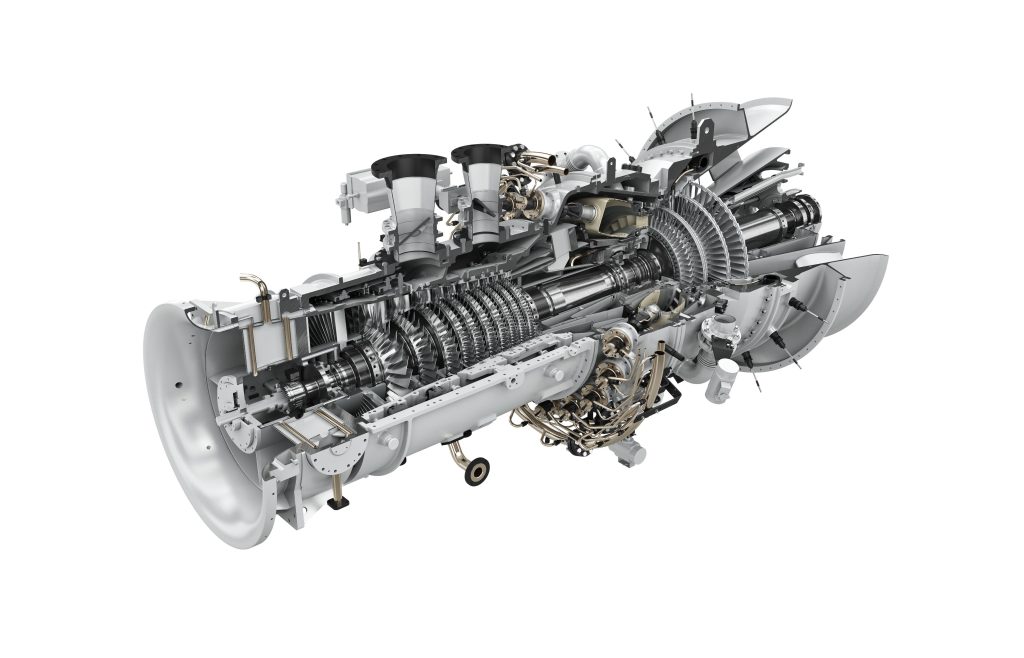

Gas turbines are a rotating internal combustion engine from the family of turbo machines. This device, by burning fuel together with compressed air and the passage of expanded gases obtained from a number of rotating turbine discs, causes the rotational power of a shaft and creates thrust reaction force or a combination of both

In gas turbines, the compressed and high-heated gases are expanded by moving between the turbine blades, which results in the production of output axial power and thrust, or a combination of both

As the name suggests, gas is used as energy in gas turbines, and the energy obtained from gas is much cheaper than the energy obtained from water vapor used in steam turbines. Also, in a gas turbine, when there is no gas for some reason, diesel liquid fuel can be used. These two factors are among the most important advantages and privileges of gas turbines. Because these turbines are rotated by the force of gas expansion, they are called Turbo Expander

To use the energy in gas or diesel, they must be burned in the vicinity of air. Therefore, the gas turbine must have a combustion chamber and an air compressor. In general, a gas turbine consists of three main parts: compressor, combustion chamber, and turbine. Also, the air intake and exhaust equipment include the first part and the last part of a gas turbine, respectively

The basis of work in a gas turbine is that in the first stage, a large volume of air is sucked into the compressor after being purified by filters with atmospheric pressure and ambient temperature through the inlet called Engine Air Inlet. It faces an increase in temperature, an increase in pressure, and a decrease in volume, and finally, the air comes out of the compressor with high pressure and temperature

In the second step, the compressed air enters the combustion chamber through the airflow channel. In this section, by injecting fuel, combustion takes place at constant pressure and a flame is formed. In the process of combustion, the gases undergo volume expansion and finally the hot compressed expanded gases with high pressure and temperature leave the combustion chamber

In the third stage, the working fluid enters the turbine section and by overcoming the resistive force and doing the work, it sets the turbine blades in motion and causes the rotational power of the shaft, and creates thrust reaction force or a combination of both. In the turbine part, the fluid faces a pressure drop while passing through the blades and expands until it reaches the ambient pressure. Finally, the fluid with atmospheric pressure and high temperature leaves the turbine and enters the free environment through the exhaust

The compressor used in gas turbines is mostly of the centrifugal or axial flow type, which consists of several rows of fixed blades and rotating blades. In order to compress the air from one stage to the next, the vanes are placed in such a way that they get smaller from the inlet to the outlet

In the turbine part, the necessary energy to overcome the friction force, and turn the turbine and other equipment that are mounted on the turbine axis must be provided, which is the same for all types of water, steam, gas, and wind turbines

A lot of energy is needed to perform the above steps, so to produce more energy, the volume of air that enters the combustion chamber must be much more than the air needed to burn gas or diesel. When the combustion occurs, the excess of the incoming air is also heated and its volume increases and its pressure rises. Therefore, the building of the combustion chamber is built in such a way that the air coming out of the compressor cannot extinguish the flame in the combustion chamber due to its pressure

In the turbine, the position of the fixed and rotating blades is the opposite of the compressor, and they get bigger from the inlet to the outlet respectively. This increase in the length of the turbine blades is for pressure drop and speed increase, and this means the conversion of pressure energy into kinetic energy. The compressor part and the turbine part can consist of a consecutive number of stages (each stage is a disk on which the blades are installed)

Steam Turbine

In steam turbines, the steam power produced in the boiler is used to drive the turbine. Hot steam is expanded in a nozzle with a pressure higher than atmospheric pressure, and as a result, part of its thermal energy is converted into kinetic energy, and based on the impact or reaction principle, it converts it into mechanical energy

In general, the building of steam turbines consists of two main components, including fixed parts and moving parts. Fixed parts include nozzles, bearings, housing bearings, diaphragms, guide vanes, steam chamber, throttle valve, stop valve, safety valve, governor, seals, lubrication system, etc., and moving parts include: rotor and accessories such as Moving vanes, lubrication rings, coupling, maximum speed system, protection systems, etc

Types of Steam Turbines

This naming is based on the geometrical scheme of the equipment or in other words based on the number of cylinders

Single-cylinder steam turbines

Combined steam turbines

Steam turbines with a capacity of 40-60 MW are generally single-cylinder machines, and larger units are usually of the combined type, and the steam is partially expanded in the first cylinder, and then the expansion is completed by passing through one or more cylinders. To maximize the efficiency of the turbine, steam is expanded and worked in several stages. These steps are categorized according to how energy is extracted from them

The advantages of using steam turbines are

High efficiency

High reliability

It has a simple building

Low maintenance cost

It has the ability to change rounds and also produce high rounds

The disadvantages of using steam turbines are

Needs a boiler and other related equipment

It has a high cost of producing and transporting steam and related equipment

High steam loss

Relatively difficult to close and start

High maintenance and repair costs

Limited use, only in places where steam is available, such as power plants or refineries

Hydraulic Turbine

Hydropower is a combination of vertical fall and then smooth flow of water. In this way, with a hydro machine in hand, the water that falls from higher to lower levels can be converted into electricity. The speed of water and the height of the opening known as head are two effective factors in the received energy. In fact, water does not contain any energy by itself. – If the opening has a slight slope, it needs a stronger flow. If the water flow is slow, it needs a steeper opening. One of the most obvious differences with hydropower compared to wind or solar power is that you cannot get the same amount of electricity by adding more receiver modules. Because blue energy is limited to its source and you can have all your benefits with one device. Meanwhile, wind and solar converters only need more space to produce electricity

The advantages of using water turbines are

It is renewable and is renewed naturally after each season

They are pollution-free and the electricity generation process in them is completely physical

They have high yield and efficiency. (Usually, the efficiency of hydro turbines is above 90%, and the overall efficiency of a hydroelectric power plant can be above 80% This value is a very good figure compared to fossil power plants, which are in the range of 40 to 60%.)

Due to the need for low maintenance, it has a high accessibility factor

They enter the circuit quickly and the setup time is very short, about 5 minutes. This time is interesting compared to thermal power plants with start-up and start-up time of about 5 to 6 hours (this time will be different depending on the type of thermal power plant and its hot and cold start-up)

Due to the need to build a dam and water storage, these power plants have advantages such as controlling water flow and floods, irrigation, fish farming, transportation, creating recreational facilities, etc

The disadvantages of using water turbines are

The need for high investment compared to thermal power plants

Long build time

Making changes in the ecology of the construction site

Dependence on weather conditions and rainfall

Wind Turbine

In wind turbines, wind power is used to move the turbine. Today, wind turbines are used in wind power plants to generate electricity

The basis of the work of wind turbines is that the kinetic energy of the wind rotates the blades that are connected around the rotor of the turbine, the rotor is also connected to a central shaft, which rotates the generator and generates electricity. Therefore, wind turbines convert the kinetic energy of the wind into mechanical power, and this mechanical energy is transferred to the generator through the axis and finally electrical energy is produced

Wind turbines are divided into the following two categories

Horizontal axis wind turbines

Vertical axis wind turbines

Horizontal axis wind turbines

Wind turbines with a horizontal axis have a long history and are still used today. In these turbines, the rotor and electric generator are placed on top of a tall tower and must be aligned with the wind direction. In the turbine, the wind speed is measured by a piece called Anemometer, and the obtained information is sent to the controller. The controller part starts the machine when the wind speed is within the permissible limit and when the wind speed exceeds the permissible limit (65 mph) it issues the command to shut down the machine because in this condition the generator will quickly heat up very high. Receipt. The wind direction is measured by the Wind Vane piece, and this piece helps the direction of the turbine to be in the right position relative to the wind direction

When the wind blows in the opposite direction of the turbine and the rotor must be placed in front of the wind, the yaw drive is used. The Yaw motor is used to move the yaw drive. It is clear that if the wind is blowing in the direction of the turbine, there is no need to use the deflection drive

In most of these wind turbines, a gearbox is used to convert the low rotation speed of the blades into a higher speed for the generator. But in some designs, the shaft rotates the generator at the same initial speed. Wind turbines with a horizontal axis have good efficiency, but their maintenance is difficult due to the location of the equipment at a high altitude

Vertical axis wind turbines

In vertical-axis wind turbines, the main rotor is placed vertically. These turbines don’t need to be adjusted in relation to the direction of the wind, and this point is considered a bonus in places where the direction of the wind is very variable, for example, on top of buildings. Considering that the axis is vertical, the gearbox and generator can be placed near the ground, which makes it easier to access this equipment for maintenance

The disadvantages of these turbines include low rotational speed, high torque, high dynamic loading of the blades, lower efficiency compared to horizontal turbines, higher cost of the power transmission system, as well as the high complexity of the design and analysis of the airfoil blades before making the prototype. prototype pointed out

Vertical axis wind turbines are made in different ways, the two main types of which are Darrieus and Savonius wind turbines

Horizontal wind turbines often have 3 blades. The blades usually have a length between 20 and 40 meters and in large turbines, more than 60 meters, and their rotation speed is about 10 to 30 revolutions per minute. Some wind turbine models work at a constant speed, but variable-speed turbines can produce more energy, which is driven by the lift and drag of the blades

Although wind power is considered a healthy and non-polluting source of energy, the construction of a wind turbine farm can cause serious damage to the environment of the region. Dynamite is used for digging pits if the land in the area is covered with stone, which greatly affects the ecosystem of the area and plant species. Also, the construction of roads to access the location of wind turbines causes the destruction of many wildlife habitats